|

Double Neck Project "Not For The Feint of Heart!!" |

|

|

|

|

|

Take This: |

Remove this: |

Becomes Double neck Mandolin /

Guitar!!! |

|

The model on the left was purchased off ebay for $250 - $300

If taking $300 to the band saw and cutting it up gives you shivers,

read no further!!

I apologize in advance for the grainy, slightly fuzy photos. These

were all taken with my phone. I lost my tri-corder readings though!

(some of you will get that) |

|

|

If you want to build one of these yourself. I am making a kit

available. It includes a Slotted (14.375" my favorite) and radiused

(12"R) fretboard 1/8" bone nut blank (you will need to final

shape and cut string slots. 4' of guitar fretwire. |

|

|

|

So, I have been playing more guitar and electric mandolin the last 4

or 5 years. I am always switching back and forth. I have been thinking

of a Double Neck for some time. But don't have the time or interest to

build from scratch right now. So my original thought was to take a

pre-built dbl-neck and modify it. When I saw this headless model (upper

left) I was thinking I could modify one neck to mandolin and so this is

a collection of photos of that journey. (left and right) Remove

the necks, choose the bad one to modify.

*It would be

best if you leave the lower neck where it is and modify the upper neck

as the mounts are not exactly the same. The upper neck on mine was the

better of the two but when I mounted it in the lower pocket it didn't

line up as well.*

Remove the frets with end

nippers ground flat. Remove the fingerboard with heat putty knives. I

used an iron for heat. **tip, get your own iron. Do not! I repeat, Do

Not use your wife's iron for this!! Go slow and let the heat do the

work.

Remove the truss rod. You probably should throw this in the trash but

if you are like me. Well, I won't say anymore. The fingerboard should go

to the trash even if you have the skills to get it off in one piece!

|

|

|

Truss rod removed, necks removed and the back opened up to get

to the wires. The wire from the ground and the pickups will need to be

cut and pulled through the body cavity before cutting on the bandsaw.

Left, if you are handy with welding it would be

easy to modify the original truss rod. Just cut it to length and weld

the end using the original as a pattern.

You could also just epoxy in a solid steel bar or graphite.

Because of the light gauge strings and the thickness of the neck you

probably could just inlay a piece of hardwood and it it would be fine

(but I can't guarantee that) I have had mine up and running for about

three weeks now and I still have not tightened the truss rod. But that

is just my experience with one of these instruments. Your mileage may

vary!

|

|

|

I kind of designed this as I went. But I was going from a 25.500"

scale down to a 14.375" scale and that means moving lots of stuff

around! I have a small collection of instruments, some that I built and

some from other builders. One of my favorite electric mandolins is a

Schwab 5 string. It took a while to get used to the scale. I had always

heard it was a 14.500" But the one I have is actually 14.375" so

that is the scale I used for this project. I had to shorten the but

end of the neck blank by about an inch.

I did use a mandolin size truss rod. I am not totally convinced it

was needed. Since I strung it up the truss rod was not tightened or

loosened. I would think an inlay of graphite would be plenty good

as well, but I new I would have an existing channel to work with. The

new truss rod was taller that my channel was deep, so I elected to cut

about 1/16" one the bottom of the fretboard and leave the neck alone.

I added a little more information regarding this in the section above

but if you are here you probably already read it, if not you may want to

read that as well if you are planning to massacre one of these yourself!

The idea was to remove material from one side of the neck and remove

one string. Leaving the pickups and saddles positioned as they were. |

|

|

(left) the lower pickup needed to come out as this is where

the bridge would be moving to. Also the tailpiece was removed and the

ground wire to the tailpiece was pulled back inside the body cavity.

(right the tailpiece is sitting over its new location. I sat the new

slotted board in place and measured approximately 14.375" to get the new

location of the tailpiece. (moving saddles are a nice feature) I haven't

worked with hardware like this before. It is heavy! most of the weight

on this instrument is from these tailpieces. And it is heavy!!

|

|

|

I thought I would cut some weight down by taking some material out

of the center and also get the necks a little closer together. The

reality is that the body is made of alder and therefore very light. (the

weight was from the hardware!) but I still wanted the necks closer and

the original guitar wouldn't fit the new case I bought for it! (always

buy the case first!) Builders will understand! I removed the pickups

and wires running through the body and took it over to the bandsaw. |

|

|

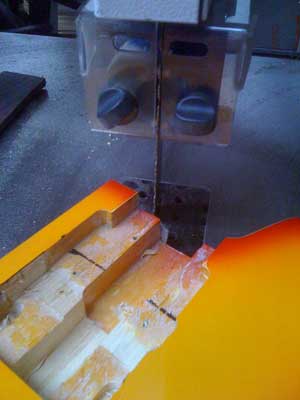

There is something really delightful about taking a new instrument

and laying on the bandsaw table. Right as the motor starts up (6 hp in

this case) the biggest smile you ever saw cam across my face!!

I was still enjoying myself at the joiner!! |

|

|

OK, enough of that! you can see that the wood was removed into where

the pickup cavity was, also the lower mortise needs to be moved. You can

use a router for this but be careful if you do. This alder body responds

well to a hammer and chisel! (which is what I wound up using. A wise man

said that "if you see your problem as a nail, the solution is always a

hammer!!" OK, you can see I have the lower receiver in its new

location (on right) |

|

|

With the tailpiece in its new location we need to cut the body

again. Oh boy! Oh boy! to the bandsaw!! |

|

|

(left) Not super clear but I was hand-holding all this together to

get an idea of where to cut it all.

(right) you can see the original configuration of the headless

locking nut. This needs to be moved and heavily modified. |

|

|

I cut this with a hacksaw using a vise. Then to a disk sander

to clean it up. |

|

|

(left) Here is the new 5 string head. and the cut off neck with the

new truss rod in place.

(right) Gluing the new fingerboard on to the modified neck. I love my

new zip tie method. This worked very well. It has always been a

challenge to clamp round surfaces together. Thank you Lord for this

great ides! To bad I can't patent it. There is probably some other poor

luthier that did this somewhere. Seems like when you have a good idea

there is someone somewhere trying to find a similar solution to a

similar problem!!

I think this method would also work for gluing our

Fender vintage veneer type fingerboards

on those old Fender necks! |

|

|

Here are the two halves.

(right) We need to cut the neck down and modify it.

|

|

|

(left) Oh boy! Oh boy! to the bandsaw!! I trimmed to the edge of

the fingerboard. Careful, not too close!!

(right) Recarving the new mandolin profile on a belt sander. I kind

of like a little bigger neck. I also used the neck I like as a rough

dimension. |

|

|

The mounting bracket needed to be cut down and modified. I did this

with a hacksaw and drill press. |

|

|

Getting closer! Need to modify the new mandolin neck pocket.

(right) This was a bit of a rough cut! Oh boy! Oh boy! to the

bandsaw!! OK this is getting old now. I promis I won't say it again! |

|

|

(left) Brad point drills shell dots and

centerlines. (right) Once the inlays are finished it is time for

fretwire. I used our AG-74 guitar sized fret wire.

I prefer it to mandolin size.

I should say here that I originally radiused this fretboard to 7.5"

because that was what my favorite neck was, but our fretwire is

happier working over a 12" radius so I re-radiused this board after the

fact back to 12" using one of our radius

blocks. I don't own one of the fancy fret rollers to change the

radius of the fretwire. And as usual I was in a hurry so my advice is

forget the 7.5" radius and just use 12" I have been playing and it seems

just fine to me. |

|

|

(left) Splice and solder the wires back together. I like to use heat

shrink tubing on splices. Don't forget to put your ground wire back

under the receiver part of the tailpeice. |

|

|

Things that didn't go as planned! I am not completely sold on this

nut idea!

Because it was not located deep enough, it wouldn't hold the string

tight enough to the zero fret. The neck was alredy carved and I didn't

have room for more mods at this point.

The solution was to cut a Fender style nut in by hand. (I much prefer

the bandsaw but....)

I took a fret saw and sliced right in front of the locking nut. Then

I pulled the zero fret back out. "never enough time to do it right

but plenty of time to do it over!!" |

|

|

(left) The chisel is one that I modified by re-grinding a 1/4"

down to a 1/8" wide chisel. I has come in very handy over the years and

here it is in service again! So I got so involved making the nut I

didn't think to take any photos! A whole chapter could be given to this.

I will confess that I used a piece of pre-ban scrap scrimshaw ivory for

the nut blank making this instrument totally illegal and subject to

confiscation.

I had bought some of the old scrimshaw cut offs from our old pal the

Duke of Pearl way back. And in talking with Chuck, the way he

understands the new government regulations is that as soon as something

like this touches a tool and is transformed into something else the laws

governing it are the date it came in contact with the tool making it

illegal to own trade, transport or sell.

I actually quit using Ivory for nuts and saddles years ago but now I

don't know what to do with these little scraps I have. Same with the few

scraps of Brazilian rosewood.

I think our government should create an amnesty program where we

could turn it all in, sort of like the hazmat drives. Olly olly oxen

free, free, fee!! (oops, I meant free!)

|

|

|

OK back to the other original neck. I didn't notice before but the

original nut was miss fitted. (right) sorry for the fuzzy's but even

with bad photography you can see this isn't right! It is up in the air

about 3/32" Maybe this is the First "Air Locking Headless Nut!!"

It would not put enough down pressure on the zero fret to note

properly. It was about a half a note off. Being a good player but

not a great player I don't need this king of a handicap!

My options were to make another nut like I did for the mandolin neck

or to try to re-mount this hardware.

I chose the second as if it didn't work out I could always revert to

the first. |

|

|

Pretty much just remove the hardware take a sharp chisel and mortise

it down a bit. |

|

|

Fill the original screw hole with a toothpick and glue.

(right) Hold the hardware with a clamp and re-drill a new locating

hole. Re-mount. |

|

|

(left) The fretwork on these cheap instruments is sometimes pretty

rough. So I took a little time to take the sharp edges off. |

|

|

Back to the mandolin nut. Just to finish it out a little better I

took the far right string lock and ground it off so it wasn't sticking

out so far. |

|

|

Well here it is for better or for worse! That is pretty much it. One

unexpected consequence was by taking out the lower pickup on the

mandolin side. The pickup selector switch acts like a cut off switch

when it is the far back position. So you can turn the mandolin side off

when moving to guitar. On the down side. It is heavy but it was a fun

project. I don't know that I would do this again. Well, I shouldn't need

to! I do have plans for something similar to an SG style guitar. Cutting

the twelve string neck off and mounting a mandolin neck. Will keep you

posted. By taking the 1" out of the middle it does fit the case now

but barely. If I were to do it over I would have taken 1.5" out. I may

take it back to the bandsaw and take another .5" out. But I must

consider my motives. Do I want it to fit the case better or do I just

want to have the experience of cutting the guitar in half again??? I

can't be sure!

The photo to the right is before the bandsaw escapade and you can see

it just won't fit.

I may put a little kit together here for those who would like to do

the same. Look for the button on this page as I won't list it elsewhere

on the site. Also not to be a snob or anything but I won't have time to

talk about this or give any advice regarding this. The sum of my vast

knowledge is all right here! I would be making stuff up to talk any

further about this!!

|

|

| |

Now as Paul Harvey says "For the rest of the story." |

|

| |

The Good, The Bad & The Ugly!! |

|

| The Good!! From this side it looks just fine! This is the side I

will choose to remember!! |

|

|

| |

And Now for the rest of the story. This was an experiment and a bit

of a prototype. It can always be improved but there are some pitfalls.

These details don't really bother me, from my viewpoint the instrument

it looks just fine! But I thought I should be fair and show some

of the less attractive sides of this modification. (mod) |

|

|

This is the underside of the new neck and pocket and you

can see where I cut through the original mounting screws. These really

mess with the sound when you play a minor chord! NOT!!! Sorry for my dry

sense of humor but you get my meaning. It isn't pretty but it works! And

it could be improved on! |

|

| |

The paint is actually a nice thin finish, but it chips

very easily! If chipped paint bothers you, you should plan on

refinishing the entire body when you are finished with the mod. I will

consider mine a Relic by Randy!! No extra charge! Well There you have

it. The Good, The Bad & The Ugly!! |

|

|

|

|

| |

|

|