Installation of Allen TR-1

This applies to Godin, Tacoma and

other flat top mandolins. |

| I read recently a few items about someone not being

able to install one of our tailpieces on a Tacoma mandolin. And this

Godin is a very similar situation. I wanted to try out one of the

Godin A-8 models so I ordered one. It was a B stock instrument and

when it showed up I was surprised to find the tailpiece cover packed

in the case instead of on the instrument.

I would like to think they sent it this way because they were

concerned about it coming off in shipping, and that may be as second

reason. The first reason I am sure is because the cover wouldn't stay

on long enough to even get it in the case. The loose cover was

actually all I found to be wrong with this instrument which was great

for me as I was going to throw the tailpiece in the garbage anyway!!

The TR-1 is a good choice for this although I believe the AR-2 and

the TR-3 would work as well. The TR-2 would be more difficult (not

impossible but difficult) to deal with in this situation so I would

put it on the bottom of the list in choices. |

|

|

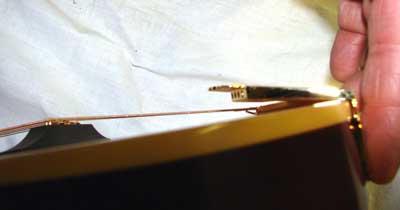

Here you can see the original tailpiece. It is

interesting to note that the tailpiece is resting and making contact

with the top of the instrument. The strings resting on the leading

edge are actually applying downward pressure on the top and this is a

flat top instrument! There is absolutely no way that our cast

tailpiece would put more pressure on the top than this stamped

tailpiece as a few self appointed "experts" have implied. See other

photos on this page and you will see that our cast tailpieces actually

do not contact the top of the instrument and the string angle is very

similar to the stamped model. What does happen is that our tailpieces

being solid and much more rigid than a flimsy piece of tin will

transfer the vibration of the string to the instrument with more

efficiency. This tailpiece sounded horrible and the instrument

had an abundance of buzzing and rattles even without the cover being

installed. |

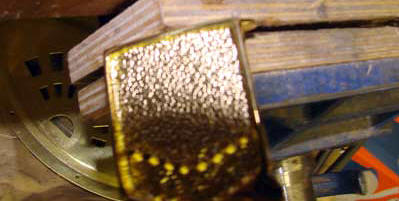

| As you can see in this photo, our TR-1 sits

quite a bit higher than the stamped model. These are set up for

installation on the usual carved arched top instrument. We need to

adjust the cast tailpiece to better fit the closer to 90 degree angle

of this instrument. This is probably more easily accomplished with an

unplated polished bronze model, but we are going to use a plated one

here. *note. The tailpiece will probably wind up with a few

light scratches from this process. |

|

|

The first thing we want to do is to tape the bridge in

place so that it doesn't move around. This one being an electric will

have a wire down through the top so it probably wouldn't drift too

far. But the tape will keep it located so you won't have to struggle

too much to get the intonation where you want it. Then of course

remove the strings along with the stamped tailpiece and strap button. |

| The next thing we'll do is to tweak the tailpiece to

better fit the instrument. I usually like to recommend that if you

need to adjust the tailpiece to adjust it over the body instead of the

end of the piece. Since we have so far to go we will need to do both.

Start by placing the tailpiece in a vice. Use some type of protection

for the finish. The material we are using should be available at your

hardware store or even at a grocery store. Apply enough force to

bend the part slightly. Take it out of the vice often and check its

fit on the instrument. You do not want it to fit like the old one so

don't worry about trying to get it to touch the top. We don't want it

to touch the top!

|

|

|

The safest way to adjust the back of the

tail is using a woodworkers vice with wooden faceplates. It is a

little hard to see in the photo but the tailpiece is centered on the

corner of the vice so that the corner of the vice engages as far as

possible to the underneath side of the face. "I dare you to say that

three times fast!"

Use protective material for this, the top photo was used to show

the location of the tailpiece to the vice.

Apply slight pressure to the body and check the fit often. It is

better to Adjust often that to over bend and have to bend it back. |

|

| Apply the felt to the underneath side of the leading

edge of the tailpiece. Usually the strip is supplied as one length. It

will need to be cut and mitered to fit the front of the tailpiece. |

|

|

Restring the mandolin, tune it up and you are done!! |

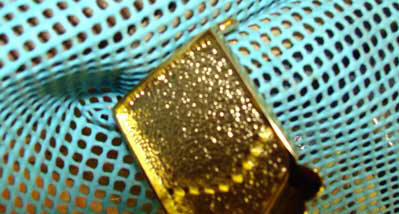

| To the right you can see the difference between the

two tailpieces. Notice that the Allen tailpiece does not come in

contact with the top of the mandolin. Also note that the string angle

is not tremendously different. The pressure to the top is very similar

to its' original state. If anything, in this case there is actually

less pressure to the top because the tailpiece is not contacting the

top. The top is free to move independently of the tailpiece and is

not dampened by the stamped tailpiece that was applying down pressure

on the top.

To purchase Allen tailpieces or our new DVD

"Installing Allen Tailpieces" click here.

Download a

PDF file of this installation procedure. |

|